Project Profile: Statue of Unity

The Challenge:

- Supply fresh outdoor air throughout the statue for the comfort of visitors, staff and maintenance personnel.

- Install supply fans in areas with very limited space.

- Maintain comfort and appropriate pressurization by exhausting used air.

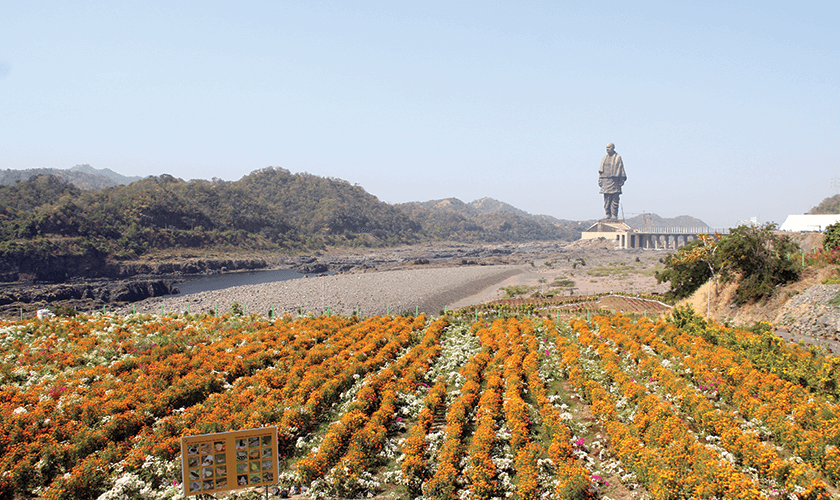

The world’s tallest statue, a tribute to Sardar Patel, stands 182 meters in the Narmada district of Gujarat, India. Sardar played a major role in establishing India’s independence in 1947 and in unifying the nation. Construction of the statue began in October, 2013 and was completed in October, 2018. The statue is divided into five zones, three of which are accessible to the public. The first zone extends from the base of the statue to Patel’s shins and includes an exhibition area, a mezzanine, a museum and a memorial garden. Zone 2 reaches up to Patel’s thighs at 149 metres. Each leg in Zone 2 contains two elevators which can transport approximately 100 visitors in 30 seconds to the viewing gallery in Zone 3 —153 metres above the base of the statue. The viewing gallery, located in the chest area of the statue, can accommodate up to 200 people. Zone 4 is the maintenance area and Zone 5 comprises the head and shoulders of the statue. Visitor comfort and safety dictated that adequate, dependable air exchanges take place at all levels of the statue.

Greenheck’s Solution:

- (16) Greenheck Model BSQ Inline Fans

- (12) Greenheck Model RA High Efficiency Axial Fans

Sixteen Greenheck Model BSQ belt drive inline fans and 10 Greenheck high performance, Model RA high efficiency axial fans were installed in the statue at four different levels: the ground floor, 58 metres, 78 metres and 121.5 metres. Two additional Model RA axial fans were installed in the basement area of the statue.

The BSQ fans efficiently supply fresh air and help pressurize the interior. Model BSQ was an ideal solution for this project because there were significant space limitations inside the statue due to civil and structural constraints. With 22 sizes to choose from, selecting a compact unit for tight spaces was easy to do. In addition, Model BSQ can be mounted horizontally or vertically for inline applications or at the duct elbow.

Two Model RA axial fans were installed in the basement to ensure adequate ventilation by providing supply and return air. The other ten Model RA axial fans were installed within the statue on the same levels as the Model BSQ supply fans to exhaust air and to maintain proper pressurization. Greenheck Model RA fans are direct drive axial fans that reduce operating costs by achieving peak total efficiency up to 86%. The unique airfoil blade design lowers sound levels.

All Greenheck Model RA axial fans and all BSQ fans are licensed to bear the AMCA Sound and Air performance seals. Greenheck’s Model RA fans are also CE certified for high temperature per EN-121101-3:2015.

Ten Model BSQ fans and nine Model RA fans also were installed in an adjoining building to the statue to supply fresh air and to exhaust air and smoke.

The Results:

Greenheck’s Model BSQ square inline fans helped the contractor achieve the desired ventilation objectives while facing difficult space challenges. Installation was quick and efficient. The square design, first developed by Greenheck, not only eliminates the need to fabricate round-to-square duct transitions, but also provides a larger discharge area compared to a tubular centrifugal fan. Greater air volume discharge reduces velocity of airflow and results in much quieter operation—an added benefit appreciated by both staff and the many visitors who tour this extraordinary, iconic landmark. “We were very pleased to work with Greenheck on this project,” said Sai Krishnan, Larsen & Toubro. “The fans arrived on time to meet our construction schedule, were easy to install and now are providing top quality performance.”