PHILOSOPHY

Putting ourselves to the test.

Design – Innovation Leading the Industry Forward

Performance Assurance

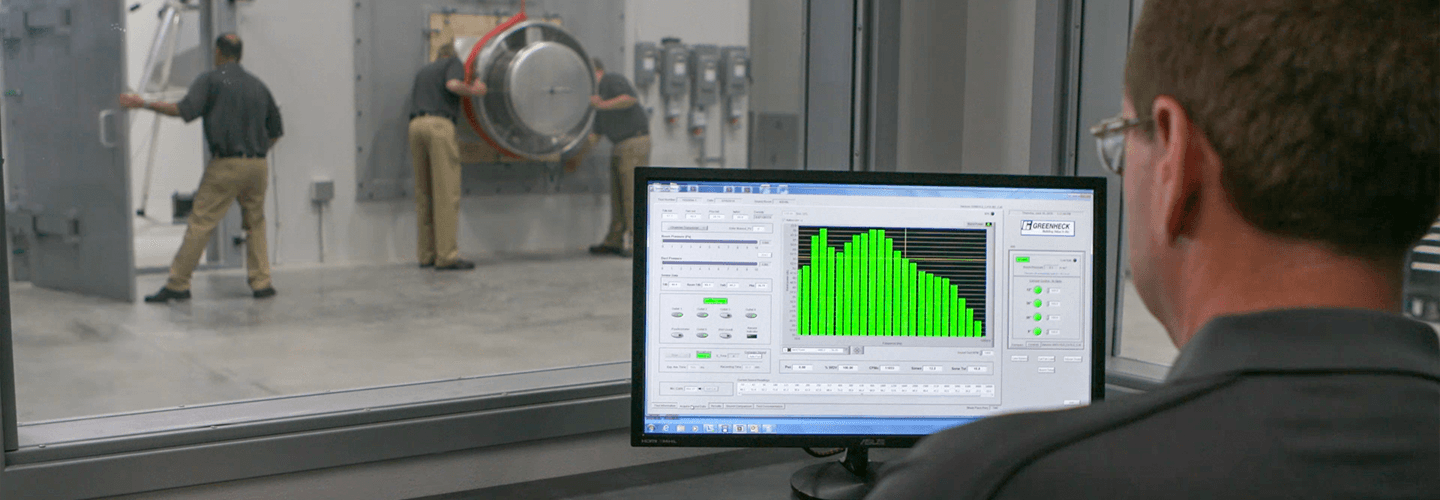

Product testing and qualification play a major role in Greenheck’s heritage and success. We conduct rigorous testing in world-class laboratories ensuring that all designs and purchased parts meet quality standards that Greenheck customers have come to expect.

Real-life, in-house testing procedures measure aerodynamic performance, sound levels, structural integrity, mechanical operation, environmental impact, temperatures, vibration levels and more. Fans are put through air and sound testing; louvers are tested for water penetration and pressure drop. Dampers are scrutinized in fire life safety testing.

In addition to performance testing, Greenheck products go through rigorous structural testing. Fans, dampers and louvers are put through life tests and cycle tests. Components such as belts, pulleys, bearings and motors are also life tested. Motors are stressed in overload and over/under voltage tests, while bearings must pass extensive L10 life verification tests. Here is just a sample of the many product development tests we use at Greenheck:

- Air performance testing

- Sound performance testing

- Psychrometric testing

- Product development prototyping & training

- Structural testing

- Overspeed testing

- Endurance testing

- UL/ETL temperature testing

- UL restaurant exhaust (grease) testing

- UL power ventilators for smoke control (high temperature) testing

- Hurricane testing

- Finite element analysis (FEA)

- Computational fluid dynamics (CFD)

- Modal testing

- Fatigue testing

- Motor testing

- Actuator testing

Certify – Making the Grade